Chengli company refrigerated truck is mainly composed of three parts: the chassis, the body, and the unit. At present, the commonly used materials for the interior and exterior of the cabin are mainly glass fiber reinforced plastic, stainless steel, and 8 cm polyurethane inside.

In addition to the material, another very important factor is the production process. This is why the same configuration, the same body material, but the price is different, as a manufacturer of refrigerated trucks, let’s take a look at how the new process refrigerated trucks are made.

1. Cutting

First determine the size of the whole vehicle and the size of the car body, then measure the chassis size, design the car body drawings, and then the technicians will start to mold and cut materials according to the drawings. The structure is reinforced, and the heat preservation is good. For example (Figure 2) the northeast wood has been cut.

2. Pressing technology

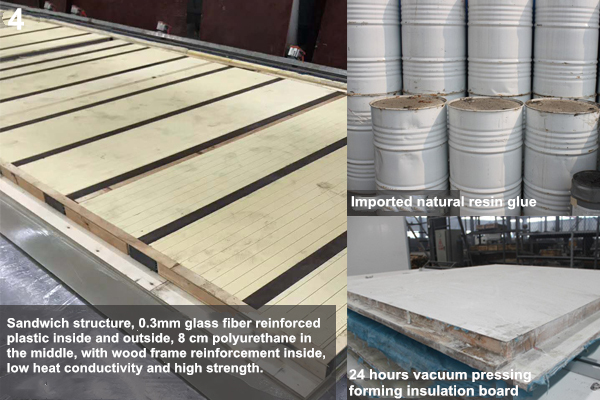

For example (Picture 3) The pressure plate of the car body is formed by an integrated 18-meter professional insulation board production equipment, using polyester wet plate making technology and glass fiber reinforced whole wooden car body frame structure, using the most advanced fifth-generation fully enclosed polyurethane in the world Plate bonding method.

For example (Figure 4) 0.3mm glass fiber reinforced plastic inside and outside the sandwich structure, 8 cm polyurethane insulation board in the middle, and wood frame reinforcement. Imported natural resin glue is poured on the sandwich structure. After 24 hours of positive pressure, it will solidify and form with high strength.

Three, splicing process

For example (Figure 5) After the plates are pressed, the next step is the splicing process of the car body. The quality of the splicing determines the strength of the car body. First, the pressed plates are spliced together on a large splicing machine, and locked with stainless steel screws. Die, seal the edges with glue around, leave for 24 hours, and splice into shape.

Fourth, the installation process of the car body

Cooling machine installation test installation accessories (Figure 6) After the completion of the splicing of the compartment body, the assembly parts, the lock handle, the profile around the compartment body, the installation door, the LED lighting in the compartment and other details.

After the accessories are installed on the car body (Figure 7), the last is to hoist the car body and install it on the chassis. Then the paint is sprayed. The whole car body process is completed, and only the unit is left.

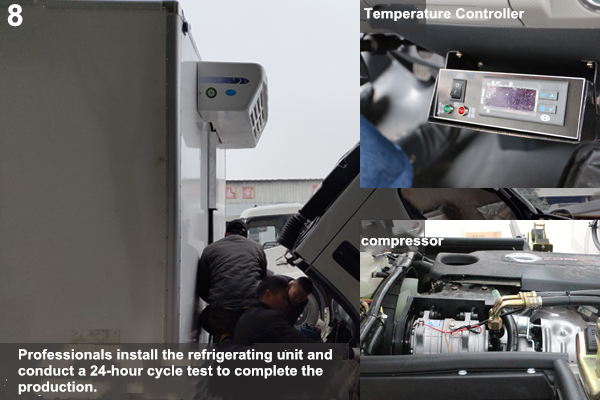

Five, cold machine installation test

For example (Figure 8) the last step, the car body is hoisted, and the unit is installed. Professionals install the compressor, evaporator, and condenser of the unit, and then repeat the temperature test. The compressor is stable and the cooling speed of the unit is tested. After that, it will be delivered to the user.

The entire production process follows the airtightness of the car body and heat preservation in more details. Natural resin glue seals the joints around the car body to ensure the airtightness, heat preservation and strength of the car body.

The board-making process in this process is a constant-temperature, constant-pressure and humidity-based board-making process. The insulation material used in this process is a polyurethane insulation board with a certain density, reinforced by glass fiber and bonded with unsaturated resin glue.

The surface of the box board produced by the board-making process is flat without foaming, and the heat preservation effect and box strength are unmatched by other methods.