JMC 5 ton Dead animal handling truck

Chassis configuration: Jiangling’s new cab, Jiangling 116-horsepower authentic National V engine, 1.5 tons at the front axle, 3 tons at the rear axle, 5-speed gearbox, exhaust brake, oil brake, 7.00R16 tires

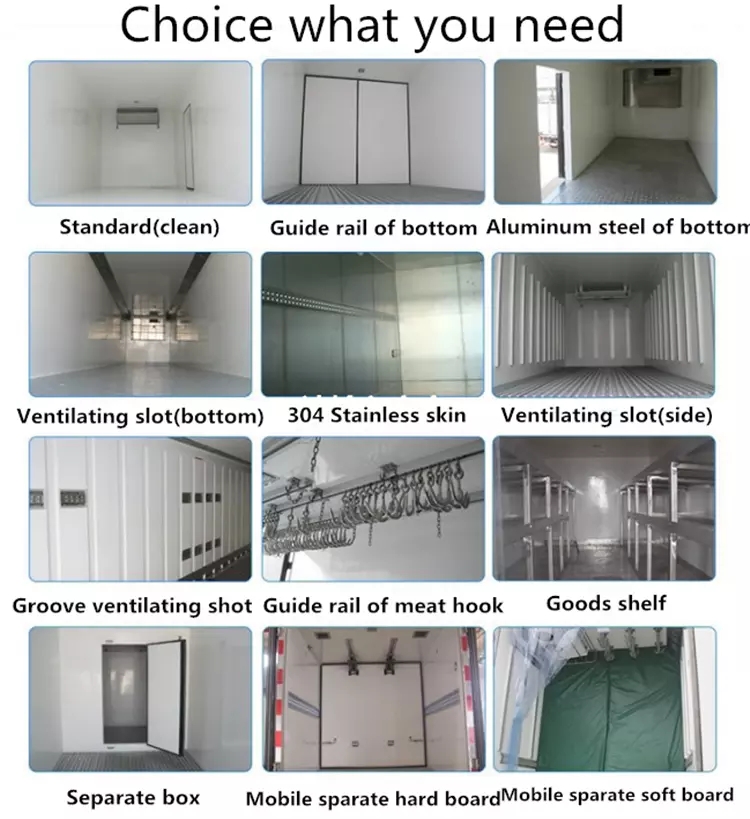

Top- loading configuration: Cargo box size: 4150*1750*1750mm. The box body is made of inner stainless steel, outer glass fiber reinforced plastic, 8CM thick polyurethane insulation layer, stainless steel door lock, with double rear doors, and Han Xue -10 degree unit. Install spray disinfection, waste liquid collection box, ultraviolet disinfection.

Optional configuration: optional wireless remote control electric hoist, car body self-unloading function, double-layer rear door insulation function.

Optional configuration: optional wireless remote control electric hoist, car body self-unloading function, double-layer rear door insulation function.

JMC 5 ton Dead animal handling truck products advantages.

1. Introduction of special technology and manufacture of vacuum adsorption equipment, good thermal insulation effect and high flatness.

2. The car body adopts the integral skeleton “sandwich” board bonding process, which is resistant to impact, corrosion and aging

3. The bottom plate adopts integral cast-in-situ glass fiber reinforced plastic, which has good thermal insulation and high overall strength; the bottom plate of the cabin is equipped with a ventilation slot, which is convenient for the cold air flow to the whole vehicle and maintain the temperature inside the cabin.

4. Refrigeration units have well-known domestic and imported units, with simple structure, convenient operation, reliable operation, low energy consumption, large cooling capacity, low noise and easy installation and maintenance.

JMC 5 ton Dead animal handling truck specification:

| Vehicle name: | JMC animal harmless collection vehicle | Vehicle model: | CLW5041XLCJ5 | |

| Emission Standards: | National Five Emissions | Chassis model: | JX10TG25 | |

| Environmental Notice: | Environmentally friendly | Dimensions: | 5995*1950*2900(mm) | |

| Fuel type: | Diesel | Cargo size (mm): | 4150*1750*1750 (mm) | |

| Total mass: (kg) | 4495 | Tire specifications | 6.00-15LT 10PR | |

| Curb weight: (kg) | 1525 | Rated passengers: | 2 people, including driver | |

| Wheelbase: (mm) | 3360 | Maximum speed: | 90 (km/h) | |

| Engine: | JX493ZLQ5 | Power: | 85KW | |

| Displacement: (ml) | 2771 | Engine manufacturer: | Jiangling Motor Co., Ltd. | |

JMC 5 ton Dead animal handling truck Working parameter:

| Insulation thickness | 80mm ester urethane | Inside and outside materials | 2.2mm FRP / Stainless steel plate | Unit brand | Domestic, imported / independent, non-independent |

| Floor material | FRP / Aluminium skid plate / Stainless steel skid plate | Installation location | Front, skirt, top | Bottom ventilation slot | Optional, aluminum alloy profile |

| Cooling time | 30 minutes | Thermal curtain | Optional | Control position | Cab |

| Meat hook | Optional | Insulation effect | 24 hours temperature rise 5 degrees | External power supply | Optional |

| Cooling temperature | Minus 20-5 degrees | Constant temperature unit | Optional | Temperature and humidity printer | Optional |

JMC 5 ton Dead animal handling truck New craft:

JMC 5 ton Dead animal handling truck Optional configuration:

JMC 5 ton Dead animal handling truck Bodywork details:

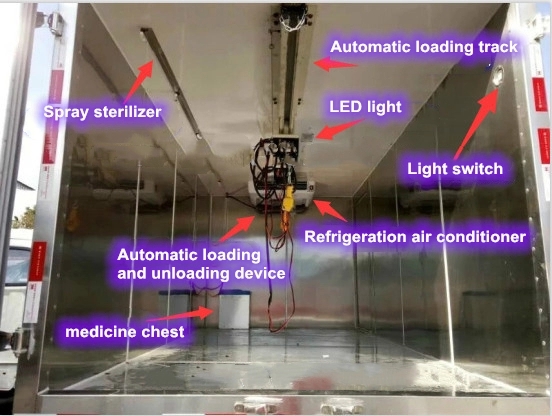

JMC 5 ton Dead animal handling truck Internal details:

Forland TOANO 2 ton minibus refrigerated truck product Display:

Pollution-free treatment truck Details:

1. The exterior of the pollution-free treatment car is made of FRP trim, the inner wall is made of stainless steel, and the material of the bottom plate is made of 6 cm thick for special anti It is convenient for the sanitary cleaning of the car body, and the handling car has the same material, production process and sealing performance as the traditional refrigerated car.

2. Refrigeration system: The vehicle refrigeration unit realizes the circulation and constant temperature of the internal space gas of the pollution-free treatment vehicle. In order to ensure the temperature requirements of dead pigs, chickens, ducks, sheep and other animal bodies during transportation The animal pollution-free treatment vehicle adopts intelligent inspection instrument to ensure the temperature in the cabin is between 0 ° and -15 degrees, and it can be in the cab. Real-time monitoring of temperature changes in the tank for easy temperature control .

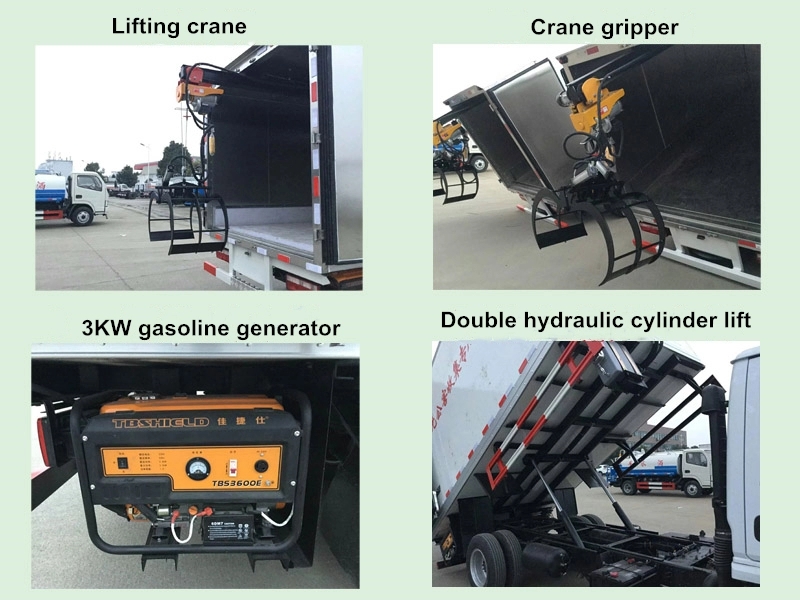

3, dragging system: consists of electric hoist, hook, lifting machine stroke and other institutions, to achieve the animal body from the ground to the inside of the box towing work, to avoid long-term contact with the animal carcass. The electric crane Has a maximum lifting capacity of 300KG and a remote electric remote control. The dragging system uses the electric winch in conjunction with the trailing tailgate to pull the animal cartilage obliquely to avoid manual lifting.

4. Lifting system: It consists of electric lifting machine, hook, lifting machine stroke (slide), wireless remote control, generator, etc., to realize the lifting operation of animal carcass from the ground to the inside of the box, avoiding the For the contact of the corpse, the maximum lifting weight of the electric hoist is 500kg-1000kg. The hoisting system is equipped with a grab hook, which is installed in the cylinder of the collecting claw to realize the clamping of the collecting claws, and It is safer and more efficient to grasp the animal corpse. The wireless operating system (remote control) realizes up and down lifting and front and rear contraction of the lifting operation by the remote controller.

5. Self-unloading system: The hydraulic cylinder at the bottom of the car body and the double hydraulic cylinder are self-unloading. After the power corpse is transported to the processing center, the self-unloading operation of the animal carcass is realized by The

system of a liquid-capacity collection is: a U-shaped waste liquid collection tank is installed at the tail of the body box, and a certain capacity collection box is installed at the bottom of the box body, and the residual waste Liquid in The tank is collected in the inner box or discharged.

7. Spray Box Spray Disinfection:. Consists of 16L Disinfection Container, Disinfection pipe, sprinkler head It IS Mainly Used for Spray Disinfection Inside The Pollution-Free treatment Vehicle Four or More Spray disinfecting Nozzles ON The Top of The Cabin Control Cabin..

8 Generator: It is equipped with 3KW gasoline micro-generator, and the transmission voltage is 220V, 6.5HZ. It supplies power to the lifting system and telescopic equipment. (Drag system without generator system)

9, UV anti-virus lamp: DC -UVC20W UV disinfection lamp installed inside the car, T5 lamp length 620mm, power 20W, UV intensity 60UW/CM2 at 1 meter.

2. Refrigeration system: The vehicle refrigeration unit realizes the circulation and constant temperature of the internal space gas of the pollution-free treatment vehicle. In order to ensure the temperature requirements of dead pigs, chickens, ducks, sheep and other animal bodies during transportation The animal pollution-free treatment vehicle adopts intelligent inspection instrument to ensure the temperature in the cabin is between 0 ° and -15 degrees, and it can be in the cab. Real-time monitoring of temperature changes in the tank for easy temperature control .

3, dragging system: consists of electric hoist, hook, lifting machine stroke and other institutions, to achieve the animal body from the ground to the inside of the box towing work, to avoid long-term contact with the animal carcass. The electric crane Has a maximum lifting capacity of 300KG and a remote electric remote control. The dragging system uses the electric winch in conjunction with the trailing tailgate to pull the animal cartilage obliquely to avoid manual lifting.

4. Lifting system: It consists of electric lifting machine, hook, lifting machine stroke (slide), wireless remote control, generator, etc., to realize the lifting operation of animal carcass from the ground to the inside of the box, avoiding the For the contact of the corpse, the maximum lifting weight of the electric hoist is 500kg-1000kg. The hoisting system is equipped with a grab hook, which is installed in the cylinder of the collecting claw to realize the clamping of the collecting claws, and It is safer and more efficient to grasp the animal corpse. The wireless operating system (remote control) realizes up and down lifting and front and rear contraction of the lifting operation by the remote controller.

5. Self-unloading system: The hydraulic cylinder at the bottom of the car body and the double hydraulic cylinder are self-unloading. After the power corpse is transported to the processing center, the self-unloading operation of the animal carcass is realized by The

system of a liquid-capacity collection is: a U-shaped waste liquid collection tank is installed at the tail of the body box, and a certain capacity collection box is installed at the bottom of the box body, and the residual waste Liquid in The tank is collected in the inner box or discharged.

7. Spray Box Spray Disinfection:. Consists of 16L Disinfection Container, Disinfection pipe, sprinkler head It IS Mainly Used for Spray Disinfection Inside The Pollution-Free treatment Vehicle Four or More Spray disinfecting Nozzles ON The Top of The Cabin Control Cabin..

8 Generator: It is equipped with 3KW gasoline micro-generator, and the transmission voltage is 220V, 6.5HZ. It supplies power to the lifting system and telescopic equipment. (Drag system without generator system)

9, UV anti-virus lamp: DC -UVC20W UV disinfection lamp installed inside the car, T5 lamp length 620mm, power 20W, UV intensity 60UW/CM2 at 1 meter.